Laser welding is a technique frequently used in industrial manufacturing processes that require high precision and speed. In this article, we will provide detailed information about laser welding operations, answer frequently asked questions, and introduce the professional laser welding services offered by 3D Robotik.

Contents

- What is Laser Welding?

- Types of Laser Welding

- Advantages of Laser Welding

- How Does Laser Welding Work?

- Precautions in Laser Welding

- Frequently Asked Questions

- 3D Robotik's Laser Welding Services

What is Laser Welding?

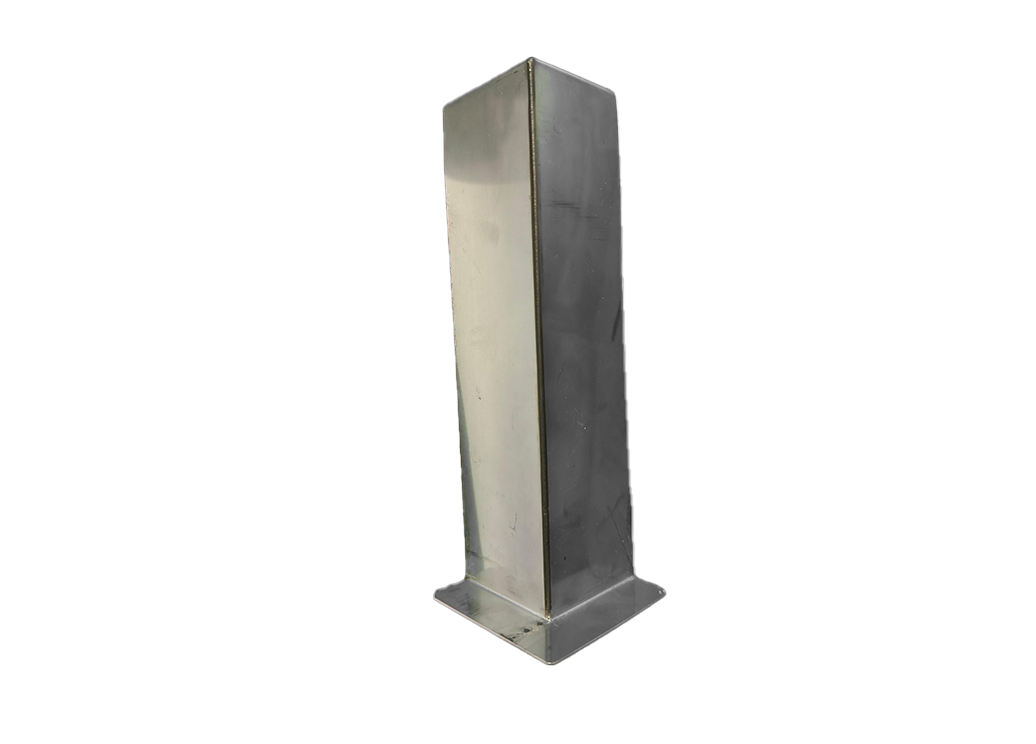

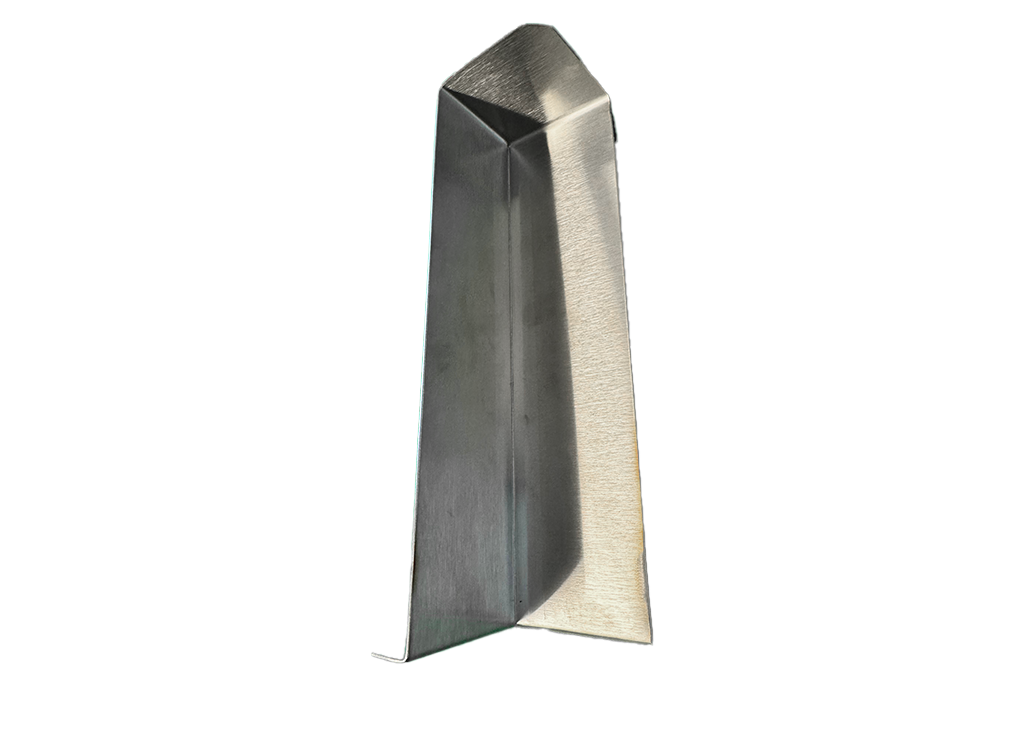

Laser welding is a process that uses the intense energy of a laser beam to join two or more metal parts. Due to its high precision, speed, and low thermal distortion, this method is widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing.

Types of Laser Welding

Laser welding can be performed using several different methods. Here are the most commonly used types of laser welding:

- Transmission Laser Welding: The laser beam is transmitted to the surface of the material to achieve bonding.

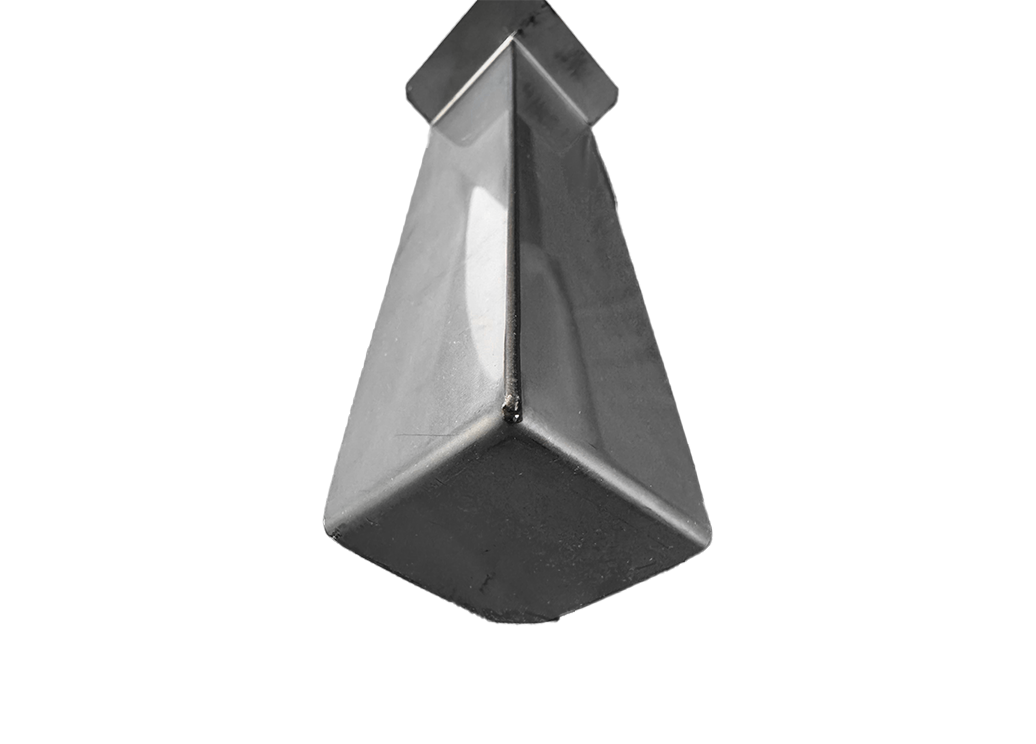

- Keyhole Laser Welding: A small hole is formed on the material's surface due to high energy density, and molten metal accumulates inside this hole.

- Conduction Laser Welding: The laser beam is focused on the surface of the material to create a conductive surface over which the welding process occurs.

Advantages of Laser Welding

Laser welding offers numerous advantages, including:

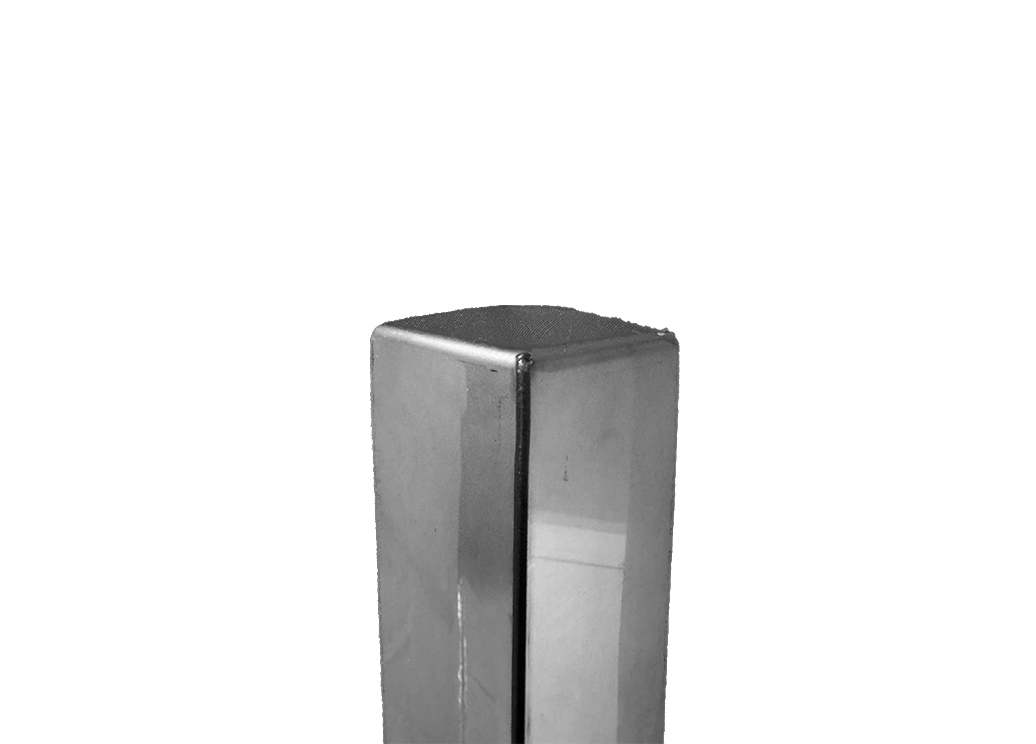

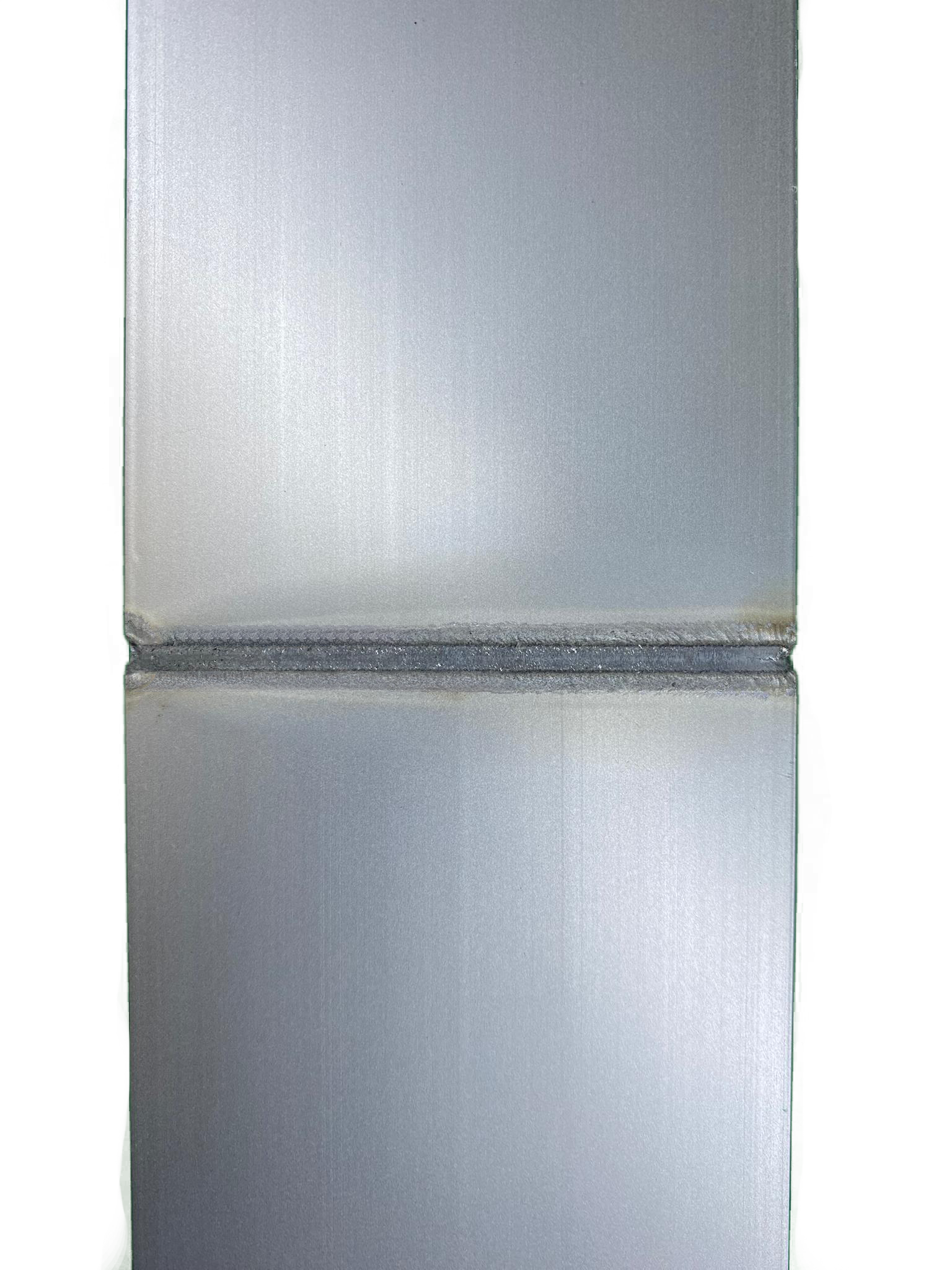

- High Precision: The laser beam offers micron-level accuracy.

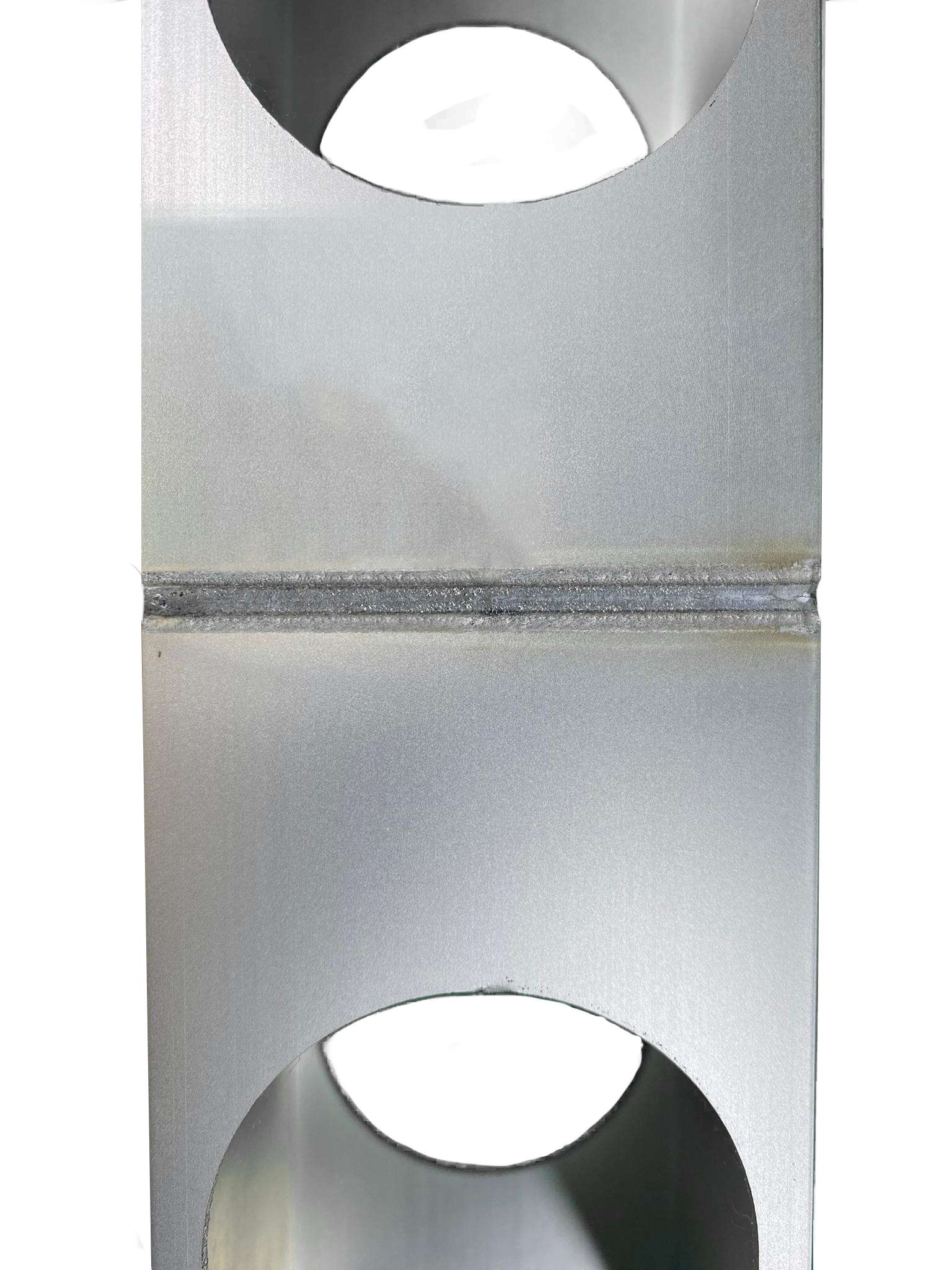

- Low Thermal Distortion: Limited heat input results in minimal thermal distortion in the materials.

- Speed: Laser welding is significantly faster than other welding methods.

- Versatility: It can be used for welding different types of materials.

How Does Laser Welding Work?

Laser welding requires the right equipment and technical knowledge. Here's a step-by-step overview of the laser welding process:

- Preparation: Cleaning and proper positioning of the parts to be welded.

- Equipment Settings: Adjusting the laser welding equipment correctly.

- Welding: Performing the welding based on the chosen laser welding method.

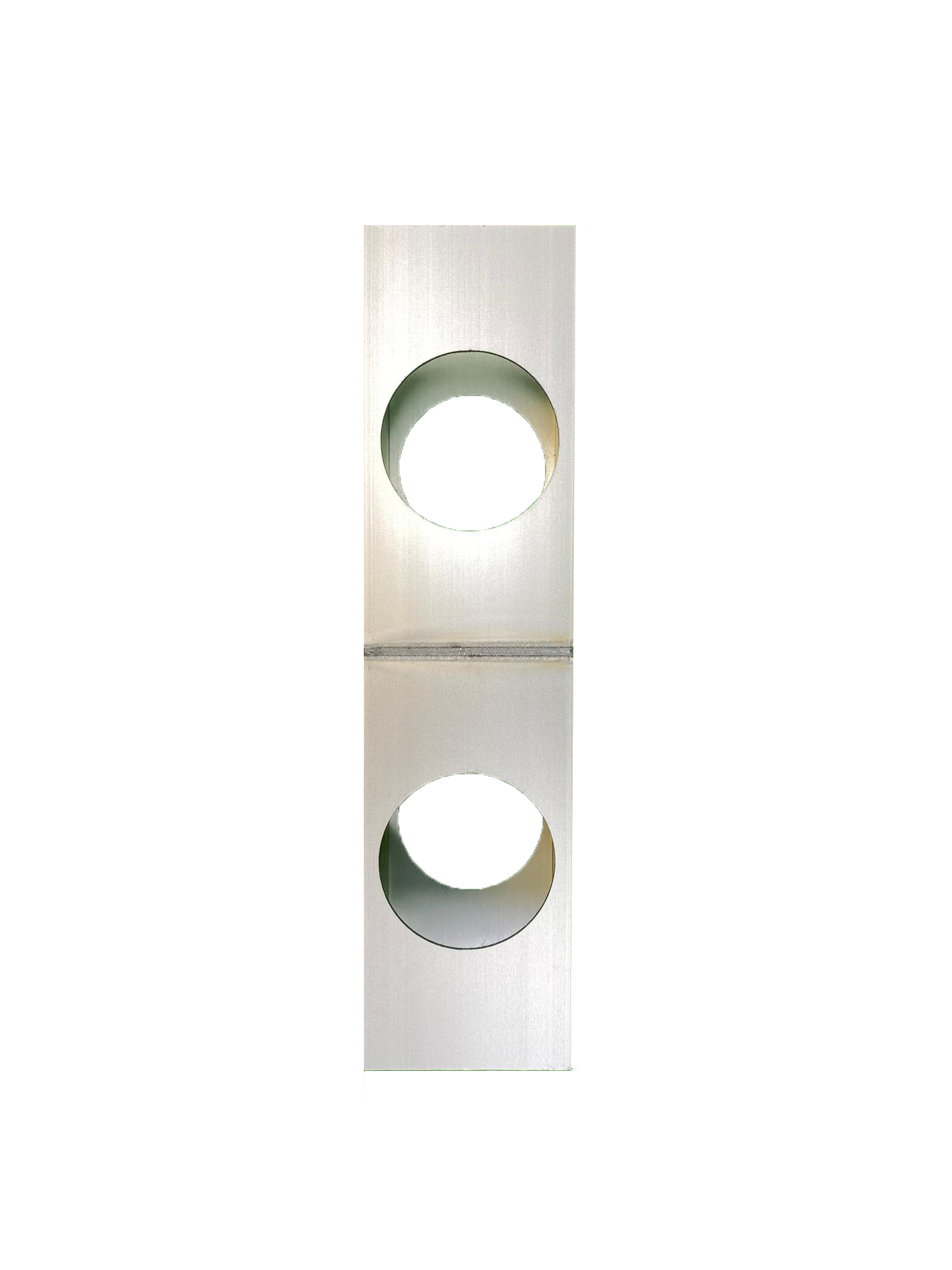

- Cooling and Inspection: Cooling the part and inspecting the weld seams after welding.

Precautions in Laser Welding

There are important precautions to consider during laser welding:

- Material Cleanliness: Surfaces of the materials must be clean.

- Use of Protective Equipment: Proper protective gear must be worn during laser welding.

- Correct Equipment Settings: Proper calibration of equipment enhances weld quality.

Frequently Asked Questions

1. Is laser welding difficult?

Laser welding requires high precision and proper equipment setup. However, with the right training and experience, it can be performed efficiently and effectively.

2. What equipment is required for laser welding?

Laser welding typically requires laser welding machines, suitable focusing systems, and protective gas systems. Additionally, safety gloves, goggles, and protective clothing are essential.

3. What gases are used in laser welding?

Gases like argon or helium are commonly used in laser welding to protect the weld area from oxidation and enhance weld quality.

3D Robotik's Laser Welding Services

3D Robotik offers a wide range of laser welding services. With our professional equipment and experienced technicians, we perform all kinds of laser welding operations at the highest quality. Our services include:

- Prototype Production: Custom prototype production services for special projects.

- Mass Production: Mass production services for high-volume manufacturing needs.

- Repair and Maintenance: Repair and maintenance of laser-welded structures.

Laser welding is an essential technique for industrial processes requiring high speed and precision. When carried out with the right techniques and equipment, laser welding provides strong and durable joints. 3D Robotik professionally delivers all the services you need in this field.