Stainless steel welding is a technique frequently used, especially in the industrial and manufacturing sectors. In this article, we provide detailed information about stainless steel welding processes, answer frequently asked questions, and introduce the professional services offered by 3D Robotik.

Contents

- What is Stainless Steel Welding?

- Types of Stainless Steel Welding

- Advantages of Stainless Steel Welding

- How to Weld Stainless Steel?

- Precautions in Stainless Steel Welding

- Frequently Asked Questions

- 3D Robotik's Stainless Steel Welding Services

What is Stainless Steel Welding?

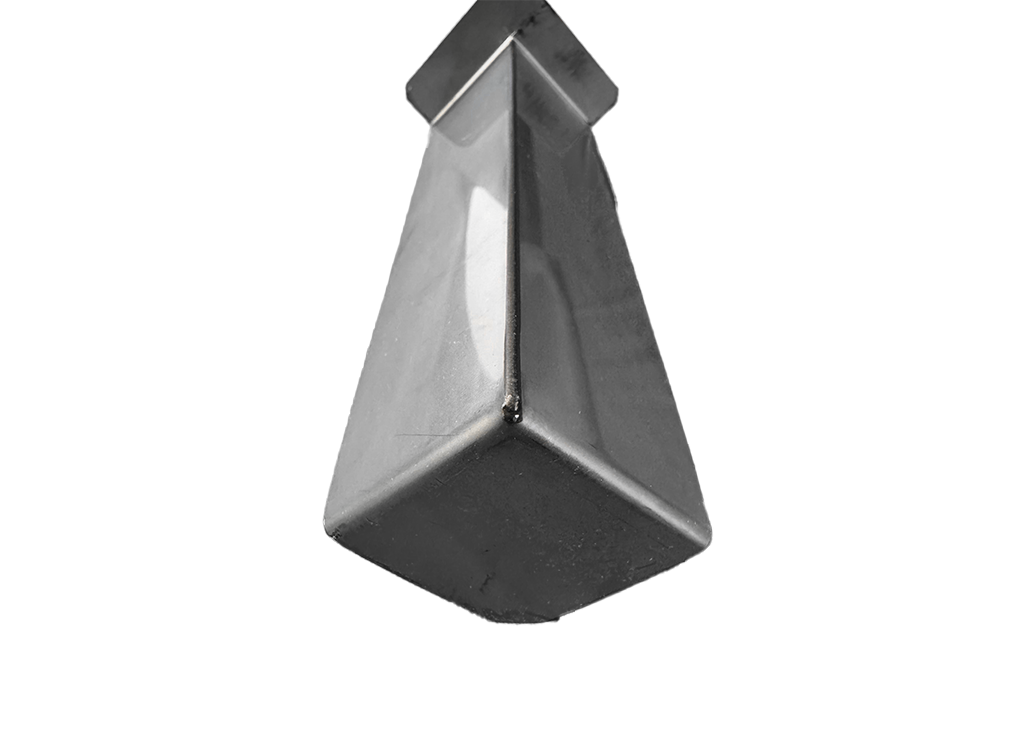

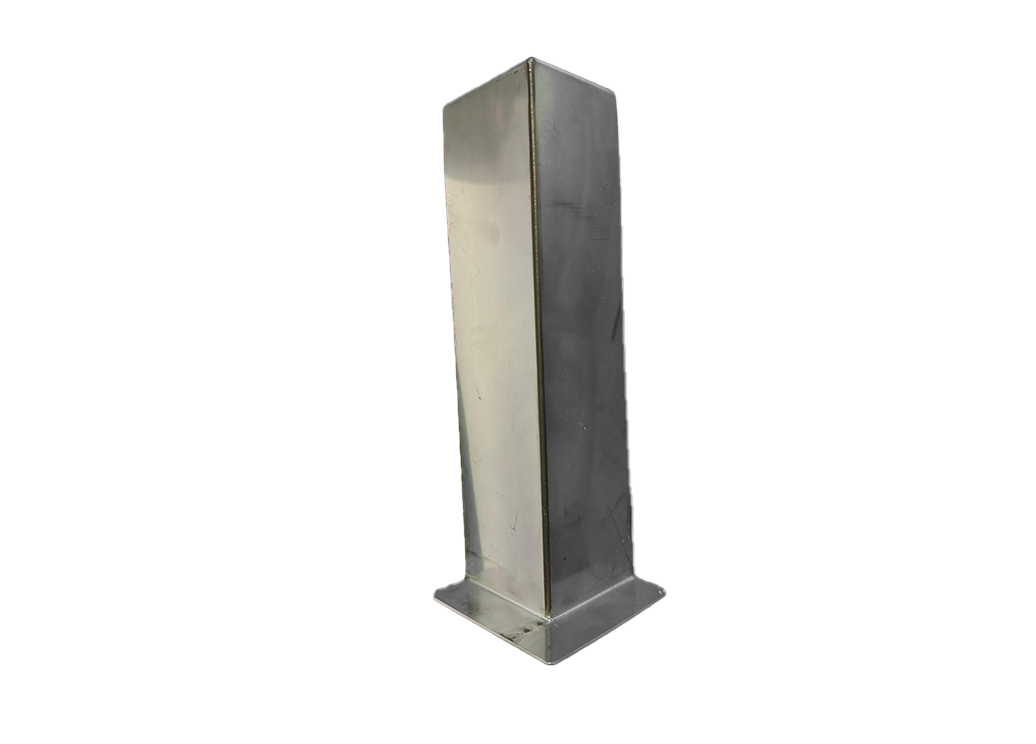

Stainless steel welding is the process of joining two or more stainless steel parts under high temperatures. This process can be performed using various techniques and is commonly used in sectors such as automotive, aerospace, food, and construction.

Types of Stainless Steel Welding

There are several different methods used in stainless steel welding. The most common types include:

- MIG Welding (Metal Inert Gas): A frequently preferred method for stainless steel welding, known for its speed and efficiency.

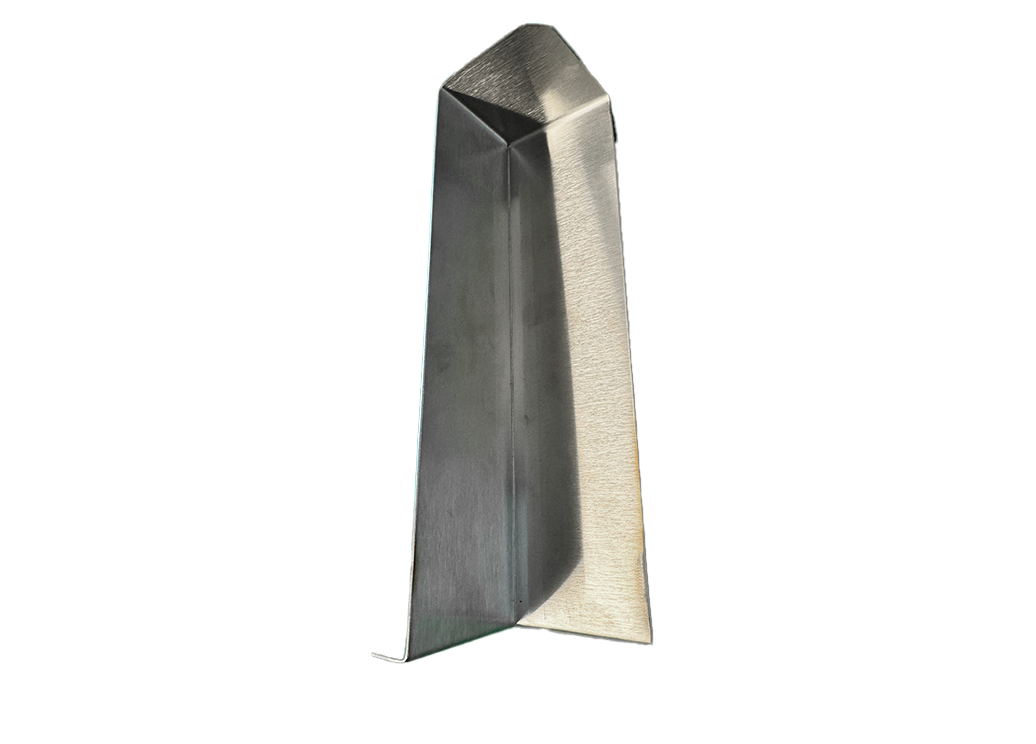

- TIG Welding (Tungsten Inert Gas): Used for obtaining high-quality and clean weld seams. It is especially preferred for thin stainless steel parts.

- Resistance Spot Welding: A method where two metal parts are joined using electrical resistance. Commonly used for thin sheet metal work.

Advantages of Stainless Steel Welding

Stainless steel welding offers many advantages, including:

- Durability and Strength: Stainless steel has high tensile strength and long service life.

- Corrosion Resistance: Stainless steel offers excellent resistance to corrosion, making it ideal for various applications.

- Aesthetic Appearance: With its shiny and attractive look, stainless steel is also preferred in decorative applications.

How to Weld Stainless Steel?

Stainless steel welding requires proper equipment and technical knowledge. Here's a step-by-step guide to the process:

- Preparation: Cleaning and positioning the parts to be welded.

- Equipment Settings: Adjusting the welding machine and other equipment correctly.

- Welding Process: Performing the welding using the selected method.

- Cooling and Inspection: Cooling the material and inspecting the weld seams after welding.

Precautions in Stainless Steel Welding

Here are important factors to consider during stainless steel welding:

- Material Cleanliness: The surface of the stainless steel must be clean and free of oxides.

- Heat Control: Stainless steel may lose strength at high temperatures, so proper heat control is crucial.

- Use of Shielding Gas: Shielding gas is essential in MIG and TIG welding for protecting the weld area.

Frequently Asked Questions

1. Is stainless steel welding difficult?

Stainless steel welding is more challenging than welding other metals. This is due to its high thermal conductivity and different alloy compositions, which make the welding process harder to control.

2. What equipment is required for stainless steel welding?

Typically, MIG or TIG welding machines, appropriate filler materials, and shielding gases are needed. Protective gear such as gloves, goggles, and clothing are also essential during the welding process.

3. What gases are used in stainless steel welding?

Argon or helium gases are commonly used during stainless steel welding. These gases protect the weld area from oxidation and improve weld quality.

3D Robotik's Stainless Steel Welding Services

3D Robotik offers a wide range of services in stainless steel welding. With our professional equipment and experienced technicians, we deliver all types of stainless steel welding processes at the highest quality. Our services include:

- Prototype Production: Custom prototype production for special projects.

- Mass Production: High-volume production services for your large-scale needs.

- Repair and Maintenance: Repair and maintenance of stainless steel structures.

Stainless steel welding is an essential technique in the industrial and manufacturing sectors. When performed with the right techniques and equipment, it provides strong and durable joints. 3D Robotik professionally delivers all the services you need in this area.